Strengths of GMC

Offering the customer a competent and flexible service has always been our priority: we work to give advice and design, for quality semi-finished and finished products. Our services are divided: co-planning, production, delivery.

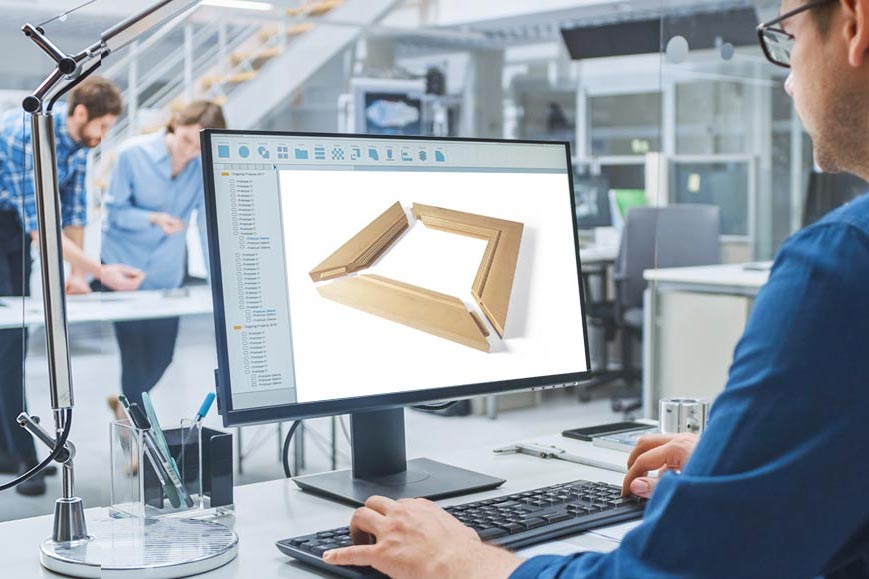

Co-planning

Starting from the technical drawing or from a sample, we make wooden components, profiles and frames. We also support customers in the design phase, developing designs and proposals for them with appropriate software through our technical office.

Quality raw materials

To make profiles or to produce wooden components we choose the best raw materials on the market. In our warehouse we always have solid wood of various types to satisfy the different application sectors: fir, beech, ash, kotò, toulipier, ayous, okumè mahogany, oak, pauoro, FJ and laminated wood, blockboard, plywood, chipboard, MDF, aluminium and PVC.

Our coverings are in different types of wood veneer, composite veneer from the various producers, melamine and digital finishing, PVC and laminates.

Respect for deadlines and costs

We work using modern logic and processes to offer the highest quality, respecting delivery times and the requirements of the customer. For this reason, we quickly coordinate the development of requests and their production to guarantee flexibility and service according to the various customer requirements.

Punctual deliveries

The finished product is packaged and delivered by us or by our trusted carriers. We are a 360 degree partner to all the companies, and we know that meeting deadlines is one of the key elements of business success.

Request information

Contact us with no obligation to find out more

about our products and processes

English

English Italiano

Italiano